This summer marked a new chapter for Centric. We launched WearLab, our very own manufacturing facility,because we believe that true innovation starts from within. Instead of outsourcing, we took full control—designing,crafting, and perfecting every piece with unmatched precision.

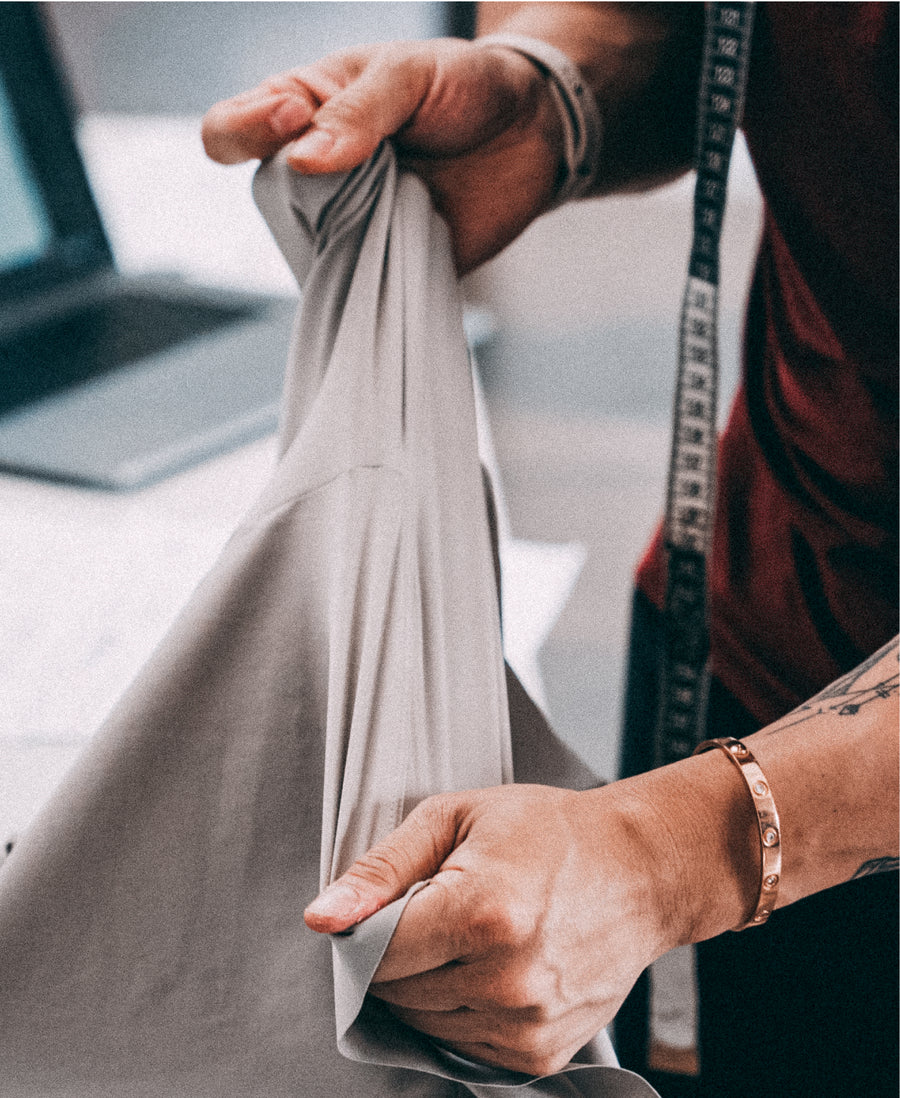

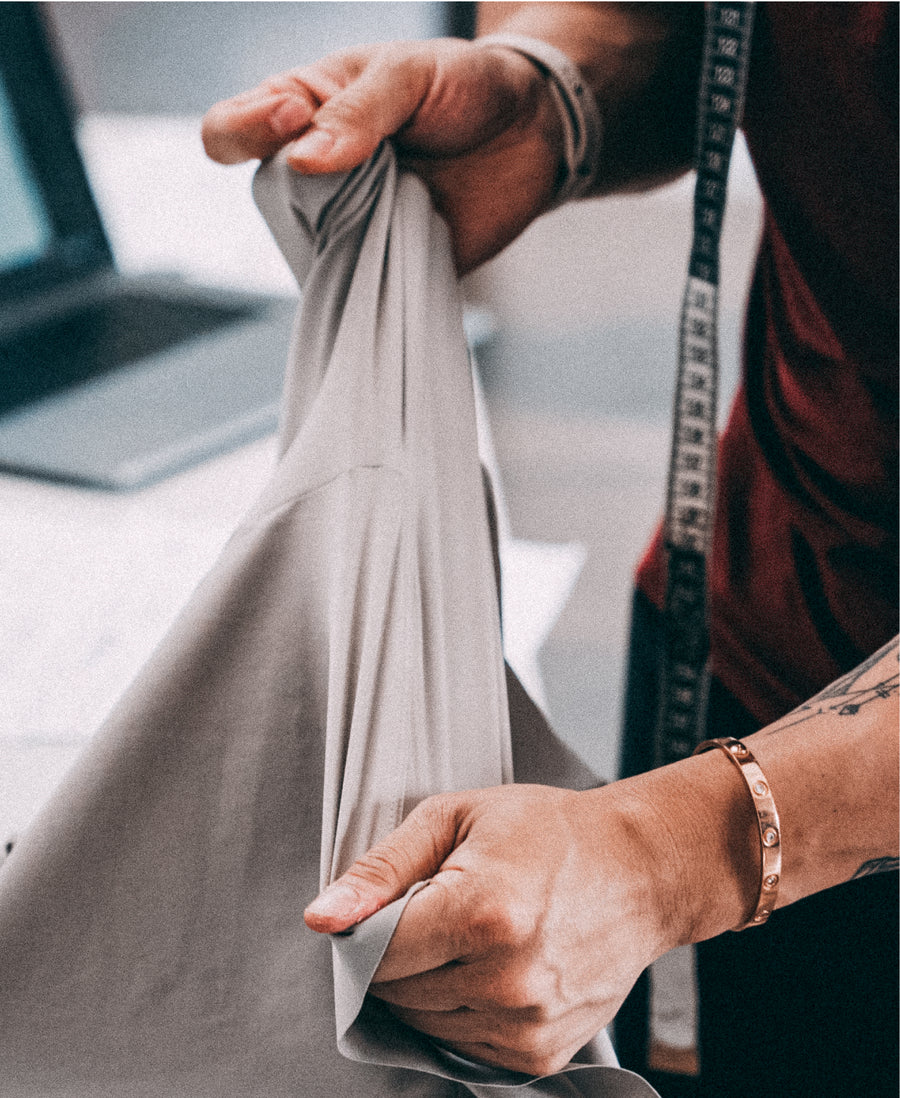

Inside Wear Lab, a team of 20 skilled artisans brings each product to life, from the first stitch to the final detail.Every piece is built from scratch—like a custom-forged blade—crafted for strength, durability, and peak performance.

By owning our production, we push boundaries in performance, durability, and sustainability—sowhen you wear Centric, you wear the best.

What is Wear Lab?

Wear Lab is Centric's own manufacturing facility. Unlike brands that outsource production,we create everything in-house—ensuringunmatched quality, innovation, and performance.

-

Athlete-Tested Innovation

Athlete-Tested InnovationDesigned, tested, andperfected by athletes

-

Precision Craftsmanship

Precision CraftsmanshipAdvanced productiontechniques for peak durability

-

Sustainable & Ethical

Sustainable & EthicalResponsible manufacturing,fair wages, and eco-consciousmaterials

-

Exclusive Control

Exclusive ControlEvery detail is fine-tuned,from fabric development tofinal stitch

-

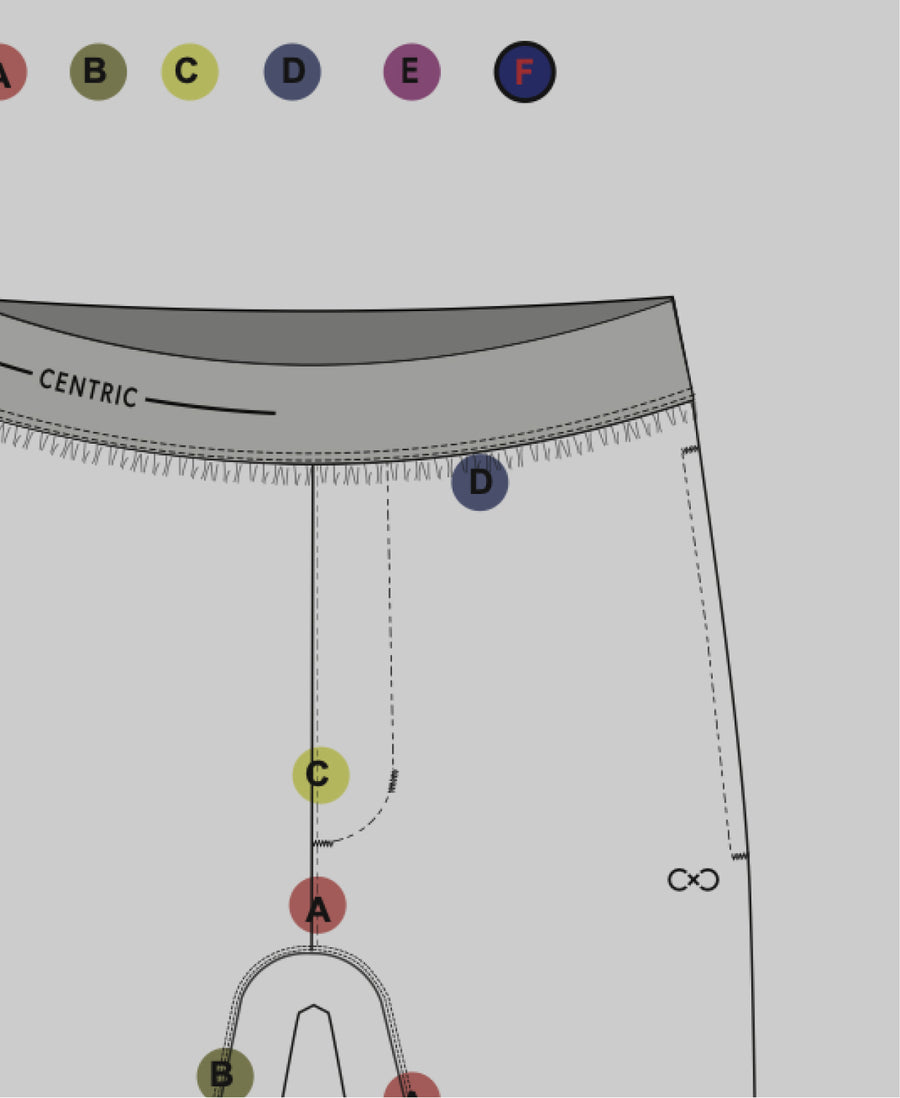

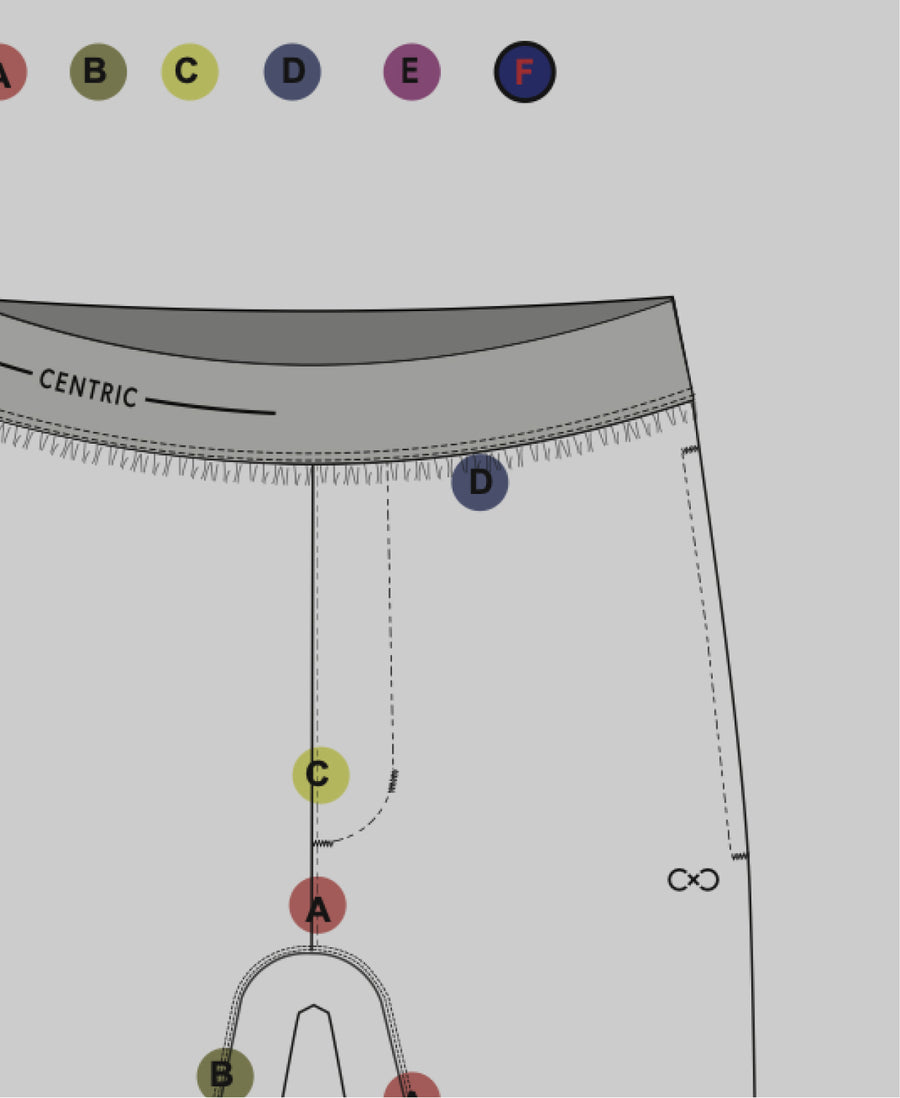

Materials & FabricTechnology

Custom-engineered fabrics designed for moisture-wicking,stretch, and durability

-

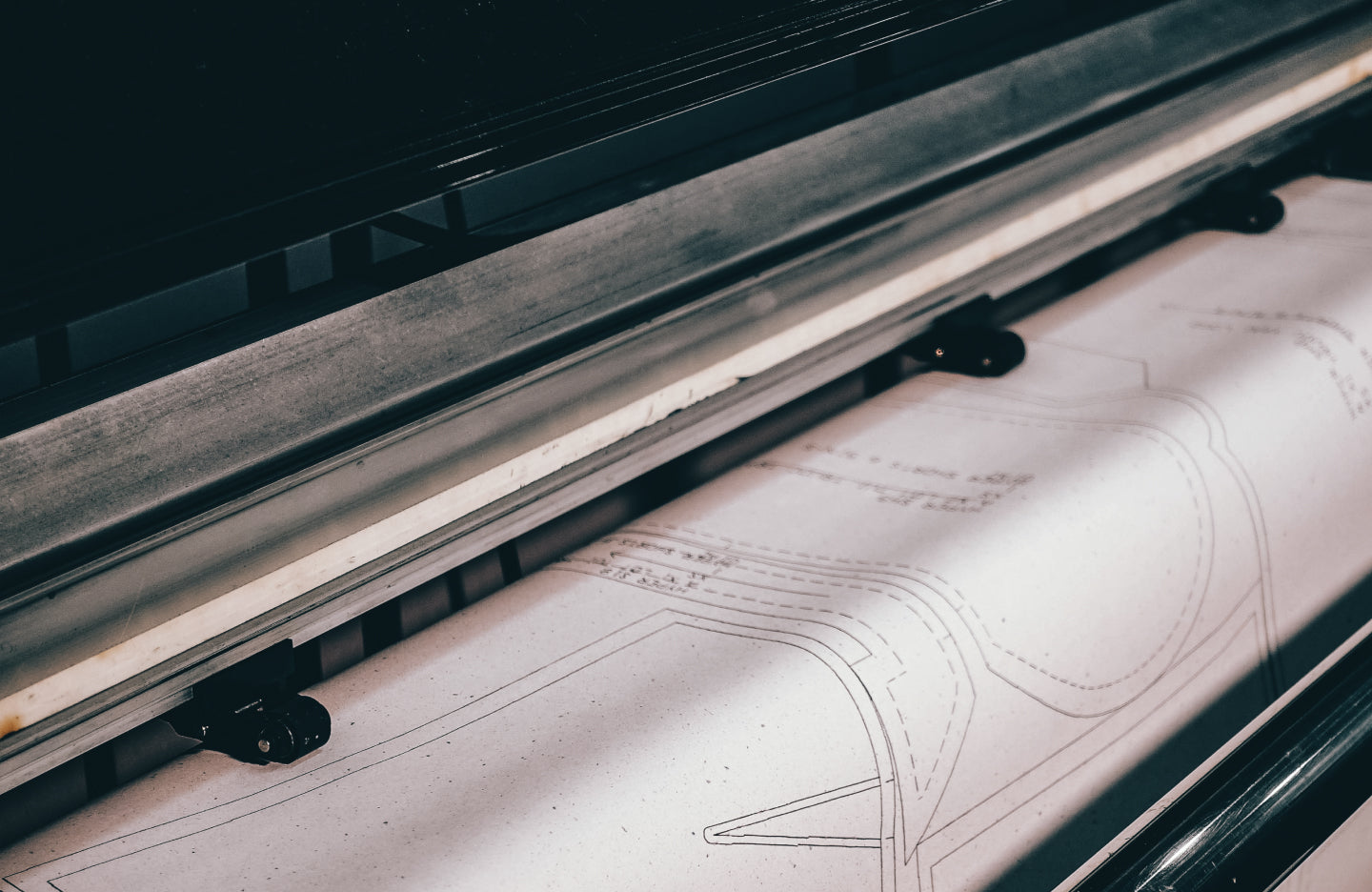

The Manufacturing Process

-

Sustainability& Packaging

Eco-friendly packaging and carbon-conscious logistics

-

Design& Innovation

Rapid prototyping, athlete feedback loops, and cutting-edge garment tech

-

Precision Production

Laser-cutting, seamlessstitching, and high-performance construction

-

Quality Control & Testing

Extreme stress tests toensure endurance in the toughest conditions

More than apparel. It’s performance engineering.

WearLab fuses biomechanics,advanced fabric technology, and real-world athlete testing toredefine high-performance sportswear.

-

Biomechanics Integration

Biomechanics IntegrationApparel designed tooptimize movement efficiency

-

Engineered for Movement

Engineered for MovementMaterials scientifically testedto aid muscle support

-

Heat & Moisture Regulation

Heat & Moisture RegulationAdvanced ventilation technologyfor peak performance

Our People

-

HUONG N.- Production Manager

HUONG N.- Production ManagerBuilt by Experts.

-

DEC D. - CPO

DEC D. - CPODesigned for You.

-

Philip N.- Athlete Tester.

Philip N.- Athlete Tester.Tested by Athletes.

Tested in The Lab.

Proven in the Field.

-

Shop Gears →

Shop Gears →“Centric’s gear holds up throug

hevery workout —nothing else compares.” -

Shop Gears →

Shop Gears →“Designed with athletes in mind.

You can feel the difference.” -

Shop Gears →

Shop Gears →"The perfect balance of durability, comfort,

and style—nothing else comes close." -

Shop Gears →

Shop Gears →"Built for performance. Moves with me,

lasts forever."